Hopper Weighing System

TWT-07

Any Existing or New Installation of hoppers can be converted into hopper weighing System. The user can get the weight data on Digital indicator, In Computer System, On Mobile Device or even by SMS.

The load cells of required capacity are placed between pedestals and the hopper. Now the hopper is placed on the load cells and the inlet and outlet lines of the hopper are also fitted with suspension bellows (if required) to enhance the performance of the system. If the outlet line (normally at the bottom of the hopper) is not fitted with suspension bellows, then the performance and accuracy of the weighment will be hampered because of continuous interference caused by the pipeline.

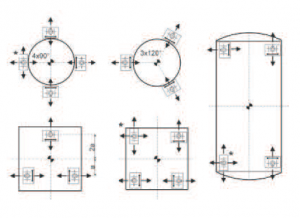

The number of load cells in a hopper weighing system depends on the number of pedestals on which the hopper is mounted. If it is going to be a new installation, then the number of load cells can be changed accordingly but if the weighing system is about to fixed into and existing hopper, then number of load cell will be same as the number of pedestals or mounting pillars.

Lower capacity circular hopper can be placed on three load cells but heavy and rectangular / square tanks should be mounted on minimum four load cells for providing suitable support to the hopper structure and maximum number of load cells can be depending on the requirement and size of the hopper.

Our TWH-07 Hopper Weighing System is designed to provide a low profile solution for high capacity vessel weighing applications. The assembly combines the compression transducer, mounting hardware with a suspension to support vessel and control the load application. This system is suitable for all indoor as well as outdoor applications. All hardware is designed according to the requirement of the system in terms of corrosive environment and any other such requirement.

Systems can also be fitted with uplift protection to protect the vessel from dismounting and also stabilizing the vessel.

The indicator part is the most vital and feature rich part of our TW-07 system. It comes with host of welcome features. Our indicators, controllers and signal conditioners as well as convertors are based on state of the art ultra – modern technologies to cater to any level of automation and needs of the customer. Be it interlinking with PLC, Computer or automating the complete system with as many features required by the customer.

Applications:

1. Big storage Hoppers.

2. Mixers, Kneaders and stirrers.

3. Dissolvers.

4. Reacting and Heating Tanks.

Salient Features:

– Easy to Install in Limited Space

– Modular design for easy installation and maintenance

– Lift off Protection

– Wide temperature range available

– Resistance against vibration

– Ideally suited for any liquid or solid weighing and accurate batch preparation for batch process weighing application.

– Simple in Design, system consisting of Quality shear beam or compression load cells meeting IP-67/68 standards.

– Junction box meeting IP-65/55 standards.

– Indicator options: Simple weight display, With power on weight display (whenever the TW-07 system is turned on, the actual weight of the material in the tank is displayed), Relay outputs for filling systems and batching systems, 4-20ma, 0-10v DC, Bluetooth.

– Weather proof and Flameproof indicators available (Optional).

Technical Specifications

Rated Capacities: 1K,1.5K,2K,2.5K,3K,5K,7.5K,10K,20K,25K, 35K,50,100k Kgs.

Full scale output (Load cell): 2.0 or 3.0 mv/v

Combined error: <0.03% FSO

Non Linearity: <0.01% FSO

Hysteresis: <0.02% FSO

Creep: <0.01 in 30 Minutes (% FSO)

Non Repeatability: <0.01 % FSO

Zero Balance: <1.0 % FSO

Insulation Resistance: >1000 Megaohms at 50VDC

Temperature effect on zero: < 0.01 % FSO /Degree Celsius

Temperature effect on output: <0.001 % FSO/ Degree Celsius

Compensated Temperature Range: 10-50 Degree Celsius

Operating Temperature Range: 0-50 Degree Celsius

Safe Side load: 100% of Rated Capacity

Safe Overload: 150% of Rated Capacity

Ultimate Overload: 300% Of Rated Capacity

Link to Video: https://youtu.be/9SVuIZwY6M0